|

project

isperom (more psi)

the story of project isperom

the 2003/2004 ford svt

mustang cobra has already etched its name �

terminator � into the history books as the

most powerful production mustang thus far.

with its base rating of 390 horsepower and 390

foot-pounds of torque, the eaton-supercharged,

cast-iron block, forged internal 4.6l is more

than an even mildly-unstable mustang

enthusiast could wish for from the factory.

throw in a heavy-duty t-56 transmission, a

3.55 gear ratio and some sinister good looks

and even the most hardcore tuners may be

satisfied. adding to its legacy, the

phenomenal handling right off the show-room

floor is eerily reminiscent of its venerable,

open-track-monster older-brother � the 2000

cobra r. with 600 pound per inch springs in

the front and rear, bilstein gas-charged

shocks and struts, beefed-up stabilizer bars,

2-piston 13 inch brembo brakes up front and an

8.8 inch independent rear suspension, the

similarities to its widely respected

predecessor are obvious. without a doubt, the

2003/2004 ford svt mustang cobra met and

exceeded the majority of the mustang-loving

population�s wildest expectations.

for some, however, the

2003/2004 terminator is merely a platform for

their dreams of a street-legal, daily-driver

super car. thanks to an aftermarket teeming

with a wide variety of well-manufactured

choices for various bolt-on modifications,

this sort of thing is well within nearly any

enthusiast�s grips. a high-performance muffler

system and an air intake put the vast majority

of �03/�04 cobras well into the 400 rear-wheel

horsepower realm. add a smaller supercharger

pulley and a custom tune and between 50 and 90

more rear-wheel horsepower can be had. for

those who want even more, bolt-on aftermarket

superchargers and nitrous oxide systems are

also readily available to catapult you into

the 500, 600, 700 rear-wheel horsepower

domains, within sight of the 800 rear-wheel

horsepower mark. these types of modifications

put the terminator on a road that very few

vehicles have ever traveled. but what happens

if that�s not quite enough?

it takes a different type

of human being to look at what most people see

as the pinnacle of high-horsepower setups and

say, �i want more.� there is one method of

forced induction that has no parasitic drag

and typically a much higher level of

efficiency: the turbocharger. amongst perhaps

the most significant reasons that most

cobra-owners shy away from the idea of a

turbocharged setup are the financial burden,

significant installation effort, supporting

modifications required and the fact that the

terminator comes with a supercharger from the

factory. but for those who simply want more,

the turbocharged route is the only option and

it is worth whatever it takes to get there.

one such person � jason

roth, of competition speed and sound, llc �

decided in april of 2005 that this was exactly

the destiny of his cobra. hearing about the

�typical� 600 rear-wheel horsepower

aftermarket-supercharged 2003/2004 cobras

ignited the desire for something different �

the road less traveled. he wanted to be able

to drive his vehicle to the local 1,320 ft.

runway, run mid 10s and drive home again while

still having the capability to go faster if

the need or desire so presented itself. for

jason, a person who�s had superchargers �

roots-style and centrifugal � and nitrous

oxide, there truly was only one form of

induction left in order to be taking on

something new and interesting. what better way

to learn more about how vehicles react to

different forms of induction and further one�s

own knowledge base? jokingly, the author of

this article believes that he merely has

supra-envy due to his southern florida

up-bringing and that he just needed a name

change on the various message forums he

frequents.

in all seriousness, it

takes a person very similar to jason �

technically, mechanically, and electrically

savvy � to undertake such a project, even with

some help. thankfully, there are even a good

number of choices for custom-fit turbocharger

systems for the 2003/2004 terminators. again,

taking the road less traveled, jason opted for

hellion power systems new

single turbonetics t76 (76mm ball-bearing)

turbocharger kit instead of a

twin-turbocharger setup. the reason�s he opted

for this kit are as follows:

- kit ships almost

immediately. no waiting months to receive

the kit

- top notch customer

service

- all stainless steel

piping

- no documented

installation problems

- when installed the kit

appears it could have come from the factory

- a single kit means

less parts to potentially have a problem

with and only 1 turbo to maintain

- the kit has been

proven at the track

this kit is rated to

support up to 950 crank horsepower and jason

intends to push the kit towards its maximum

horsepower rating. he intends to run

approximately 10 to 15-pounds on the street

and 20+ pounds at the drag strip, which should

put him in the 550-600 rwhp range on the

street and 700+ rwhp at the drag strip. with

more boost and other component changes the

900+ hp is well within reach. this setup

should satisfy the need for more power and

speed. at least we hope so�

the install

note: the following

are not step-by-step installation

instructions. this is to be used as reference

only based on our experiences during the

install. the installation of

hellion�s single-t76 turbocharger system �

assuming the right tools are at hand � is not

extremely complex or difficult. in fact,

installation is where the single-turbocharger

system may turn out to be quite advantageous,

when compared to some of the twin-turbocharger

setups available. the rest of this section

will be dedicated to a brief overview of the

steps that were taken to install the kit from

pulling the car into the bay and driving it

out.

suspension and chassis work

hellion�s single-turbocharger system

requires the removal and replacement of the

stock k-member, which cradles the engine in

between the front wheels. the granatelli or

upr k-member is standard in the kit to replace

the stock k-member.

maximum motorsports has also developed a

k-member that will fit and is offered as an

upgrade. the main reason the new k-member is

included in the kit is because of the

clearance requirements for the turbocharger

exhaust piping. the pa racing k-member will

also work with minor modifications to the

up-pipe. the d&d was installed by a customer

and apparently will work as well, but hellion

has not tested this on a vehicle. note: the

k-member in the picture is the incorrect

k-member for the

hellion turbo kit. granatelli drop

shipped the wrong one. the smaller bar that

angles back on both sides just behind the

larger bar should not be there. we had to cut

this off in order to make it work.

we

began the suspension and chassis work by

removing the rear springs and replacing them

with maximum motorsports coil-overs that had a

spring rate of 600-pounds per inch based on

maximum motorsports recommendation for a

daily driver/drag strip car. the rear coil-overs

are not required, but since the front

suspension would have coil-overs, jason saw

this as a perfect upgrade for performance and

handling. the removal of the stock springs is

done with relative ease, as is the removal of

the factory bilstein shocks. the coil-overs

were assembled, put into place and quickly

adjusted to make them equal on both sides. the

following picture shows the assembled front

coil-over setup. the rears are very similar.

we

then proceeded to the front end of the cobra.

before we started on the

k-member, we determined that we couldn�t use

the 4-post lift to do the work because there

was no unobstructed way to support the engine

freely once it was detached from the k-member.

so, we decided to go the way of the floor jack

and jack-stands. the vehicle was placed on

jack stands on all 4 corners. we then used one

jack on the front of the transmission housing

and another on the front of the engine, using

a custom-cut piece of wood that fit snuggly

against the front of engine block on the front

of the oil pan lip to avoid putting pressure

on any engine components or brackets. there

are other ways to support the engine, but at

the time this proved to be the best

alternative with the hardware we had

available. once we were confident that the

engine was entirely supported on the jacks, we

removed the front wheels, brakes, rotors,

a-arms, springs, struts and began unbolting

the engine from the stock k-member. we

loosened all 4 front k-member bolts and 4-rear

bolts and then lifted the engine less than 1

inch with the jacks to allow for clearance

between the k-member and the engine. if you

have a firewall clutch adjuster, be sure to

screw it in as far as you can towards the

firewall. if not, the valve covers may

interfere with it and damage the adjuster when

jacking up the engine. after doing so, we

removed all the k-member bolts and dropped it

out. at this

point you need to remove the oil filter and

install the oil filter relocation adapter. if

you do not do this, it will be very difficult

and time consuming to remove the filter with

the k-member in place since the k-member will

hit the filter. if you are planning

on installing solid motor mounts, please do so

at this time. after setting the stocker aside

and grabbing the much-lighter granatelli

k-member and partially installing the bolts by

hand, the brake lines on the passenger side

need to be slightly pulled and bent forward

and the same on the driver side. there is a

grounding wire for the block that also gets in

the way of the k-member. relocate this ground

wire as necessary. we then squared the

k-member to the frame, bolted it up and then

tightened to spec. we then lowered the engine

back to its original position and tightened up

main engine mount nuts to spec.

next we installed the

tubular a-arms. again, follow the instructions

provided by the manufacturer here. we ran into

problems on the passenger side and believe the

a-arm mounting points were not welded in the

proper location. we had to trim the crushed

sleeve and one of the polyurethane bushings in

order to make the a-arm fit properly. the

problem location was the rear passenger-side

a-arm mount. after the a-arms were in-place

the install of the caster camber plates and

putting the front coil-over system together

was next on the list. jason opted for the

maximum motorsports caster camber plates

to match the coil-over setup, adjustability

and quality of their parts. we then assembled

the front coil-over assembly and followed the

manufacturer�s installation instructions for

the proper spacer usage with the coil-overs. a

spring rate of 350-pounds per inch was

selected based on

maximum motorsports recommendation for a

daily driver/drag strip car. next, install the

steering rack, front brake components, sway

bar, coil-overs and bolt the tie rod ends to

the spindle. here we ran into another problem.

the front mounting bolt head on the passenger

side for the a-arm had to be trimmed due to it

interfering with the steering rack assembly.

after doing so, it fit well. some of these

problems may not occur with other k-members

and to date jason has installed a upr k-member

without any of these problems. our experience

and discussion with others is that no k-member

is a direct replacement and modifications are

typical when replacing the factory k-member.

granatelli was contacted in regards to this

and offered great customer service and was

willing to replace any parts needed.

after completing the

installation of the coil-over setup, adjust

them per the manufacturer�s recommendations

and have a 4-wheel alignment performed. jason

opted for the car to sit a little bit higher

than it did with his steeda springs for ride

quality and drag strip performance.

first thoughts of the

ride quality are overall good. bumps are felt

a little more, but not too bad. this is

probably due to the spring rates selected. the

handling has been greatly improved. jason

noticed a binding noise when turning the wheel

to the left or turning left. after further

inspection and removal of the left coil-over

setup, the spring was rubbing on the inside

fender well. there is a cutout on the inside

driver fender well that has some metal that

protrudes towards the coil-over setup. the

spring was close enough that it would rub

depending on the rotation of the spring. this

protruding metal was grinded down to allow

clearance for the springs. depending on the

alignment, this may or may not be an issue for

others.

engine work

after

doing the necessary suspension and chassis

work, it was time to start on the

engine-related work. the first job tackled was

the installation of the oil filter relocation

kit. note: this should be done when doing

the k-member. the front bumper was removed

to make the installation of the kit easier.

the kit requires drilling two or three

(depending on relocation kit) holes in the

back of your front bumper, which turns out to

be not so easy. the metal for the bumper is

very thick and takes a while to get through,

even using a smaller bit to start it off. make

sure you are using a quality metal drill bit;

this will make it much easier and faster.

after drilling the holes, simply bolt up the

oil filter housing to the bumper and screw the

relocation adapter onto the oil cooler at the original

filter location on the engine block. press in

the supplied socketless straight barb fittings

to the socketless hose. cut the hose to the

proper length making sure no mechanical parts,

such as the sway bar will interfere with the

hose. once the hose is cut to length, press in

the other fittings and connect them to the

adapter that was just placed on the oil

cooler. we found putting the socketless hose

in boiling water for a couple of minutes

helped with the installation of the fittings.

see installation instructions for any other

specifics.

next the supercharger and

stock intercooler assembly, lower pulley and

all other idler brackets and pulleys

associated with the factory supercharger setup

were removed. the factory alternator is also

removed and replaced with a 99-01 cobra

alternator and put into the 99-01 cobra

alternator location. we highly recommend using

an egr blocking plate and cap on the exhaust.

this will eliminate the possibility of melting

through vacuum lines, wire harnesses and the

aggravation of the installation, all of which

we experienced. the factory power steering

fluid reservoir bracket is also replaced with

the 99-01 bracket and is provided with this

kit.

next the 99-01 cobra

upper intake and lower intake manifold was

installed. the installation also requires the

99-01 cobra throttle cable and the throttle

cable bracket. the alternator was then

installed with the coolant crossover tube at

the same time. this may take a few tries as

our first attempt resulted in the alternator

pulley hitting the crossover tube. the

solution to this was to put a couple of

washers under the crossover tube bolts to

raise it up a little bit, but not too high.

you need to make sure that the o-rings on the

crossover tube seal in the block. the 99-01

alternator requires the installation of a ford

pigtail harness, which wires into the existing

alternator harness, but requires one

additional wire that should be connected to

12-volts. we opted to connect this to the

same location that the battery is connected to

on the relay box in front of the driver side

strut tower. follow the

hellion instructions for the most part

with the rest of the installation.

other items of note are

the sensors. there are a few on the side of

the stock supercharger that are removed and

not used. the two that remain in use are the

iat2 (intake air temp 2)/map sensor and the

frps (fuel rail pressure sensor). this is

nice because it cleans up the driver side of

the engine bay considerably. what we decided

to do was put a vacuum hose on the driver side

port of the 99-01 intake that was large enough

to fit the iat2/map sensor inside so that it

can sense vacuum and temperature. another item

of note is the tps (throttle position sensor)

has to be reversed from the factory location

due to interference with the 99-01 upper

intake manifold.

the instructions state to

bend the power steering line that is mounted

on the reservoir bracket towards the engine.

i bent it towards the front of the reservoir

instead. this seemed to work better. final

step for the conversion was to install the

serpentine belt.

intercooler plumbing and exhaust tubing

work

note:

do not tighten any nuts and bolts until

everything has been assembled and fitted loose

first.

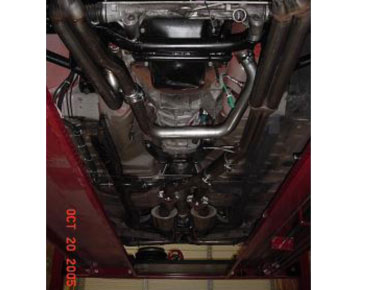

after all the engine work

was done, the plumbing for the up-pipe and

crossover tube with reducer (when using stock

exhaust manifolds) was installed. first the

exhaust was disconnected from the mid-pipe and

the mid-pipe removed from the exhaust

manifolds. be sure to unplug all of the o2

sensors prior to unbolting the mid-pipe. the

following picture was taken from under the car

after all of the exhaust tubing was installed.

it shows the crossover pipe and the up-pipe

that attaches to the passenger side exhaust

manifold and then bends down and under the

k-member to go to the front of the car and up

between the fan and engine. it also shows the

double barrel pipe that connects to the down

pipe from the turbo on one end and the mini

y-pipe on the other end where you can insert a

high-flow catalytic converter.

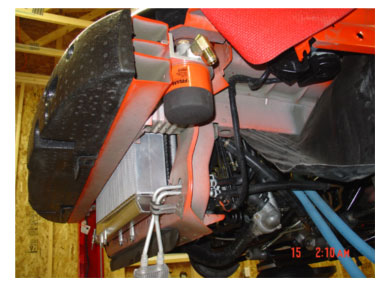

next the air-to-air

intercooler and associated piping was

installed. i have the original intercooler

that is angled. follow the

hellion installation instructions for

moving the appropriate wire harnesses and

electrical box in the passenger side fender

well. there are four mounting tabs on the

intercooler. the rear two were used to secure

the intercooler to the radiator support and

the front two i opted to cut off to allow the

power steering cooler to rotate up closer to

the intercooler. you can see the front two

mounting tabs in the picture prior to them

being trimmed. the intercooler piping was put

in place, but not tightened down until later

in the installation.

setup the turbo with the

vacuum line fitting, oil drain fitting and oil

feed fitting. make sure you use thread paste

for the oil drain billet aluminum fitting.

loosen the bolts on both the compressor and

exhaust side of the turbo in order to properly

clock it based on the instructions.

these should remain loose while it is

temporarily bolted up to the up-pipe. be sure

you bolt up the turbo bracket to the passenger

side valve cover and turbo, but do not tighten

the bolts at this time. this will help with

the proper clocking and alignment of the

turbo. check the plugs on the fan to make sure

they do not interfere with the turbo. you may

need to make some adjustments and shift the

turbo in order to clear the plugs. i removed

the lower electrical plug that is attached to

the fan and positioned it out of the way. the

plug on the top of the fan shroud should be

between the compressor and center section of

the turbo as seen in the picture with the

white arrow. in my case, to be sure i had

proper clearance i went a little farther and

removed the fan and drilled out the mounting

holes on both sides as seen in the following

pictures to increase the clearance. this may

not be required for every install, but i found

that it helped with the overall alignment in

my situation.

the down-pipe was then

installed and mounted to the turbo. be sure

the clamp and down-pipe are aligned

correctly. follow the instructions for the

wastegate mounting. on the side that does not

use a gasket, you may opt to use high

temperature rtv. if you are planning on

installing a boost controller at the same time

as the turbo kit install or later date, i

highly recommend installing the hose barb

fitting and running a vacuum line from the

additional port on the wastegate and tie wrap

the vacuum line to a safe location. it is ok

that the vacuum line is venting to the

atmosphere. access to the wastegate is very

tight and this could save time later on.

during the install it does help to have the

coolant reservoir removed to assist with extra

space. after the wastegate is installed and

tightened and the turbo is properly clocked,

tighten a few of the bolts on the compressor

and exhaust side of the turbo. loosen the

down-pipe and remove the turbo. tighten

remaining bolts that were loosened to clock

turbo except for the two that will be

tightened later for the bracket to the

passenger side head. reinstall the turbo and

use the provided gasket and put the nuts and

bolts into the up-pipe hand tight, but do not

tighten them until the down-pipe and the bolts

for the reinforcement bracket to the passenger

side valve cover have been started. tighten

the downpipe to the turbo and be sure to check

for proper alignment. then tighten the four

bolts holding the turbo to the up-pipe and the

reinforcement bracket bolts on the turbo and

valve cover. finally, bolt up the double

barrel exhaust pipe, high-flow cat or

four-inch diameter straight pipe and shorty

y-pipe. be sure to use the supplied u-clamp

for the slip connection from the wastegate to

the downpipe. finally, tighten all bolts and

clamps on the exhaust side. the previous

picture shows the underside of the car looking

from the front to back. you can see the

crossover pipe, double barrel pipe, straight

pipe and y-pipe back into the catback.

after all of

the hot side (exhaust) piping was installed

and tightened down, the filter, mass air meter

and 4-inch intake tube were connected to the

compressor inlet side of the turbo. at this

time you can orientate all of the intercooler

piping and tighten the clamps at the polished

compressor-housing outlet side. also, tighten

the clamps for the piping at the intercooler

inlet that come from the polished

compressor-housing side of the turbo. next,

install the s-shaped intake tube in the

throttle body coupler and coupler coming

through the passenger side fender well.

install the small silicone coupler on the race

bypass blow off valve and position the blow

off valve and install it on the s-shaped

intake tube with the silicone coupler linking

the blow off valve and 4-inch inlet pipe that

has the maf and filter attached to it. once

all of these parts are in the proper position,

tighten the clamps for the s-shaped intake

pipe, silicone coupler on the blow of

valve/4-inch intake pipe and the hex set

screws for the blow off valve. the intercooler

outlet piping clamps can now be tightened

down. be sure that both clamps are inside the

engine bay at the passenger side fender well

connection. the following picture is of the

engine bay showing the piping in-place.

the results

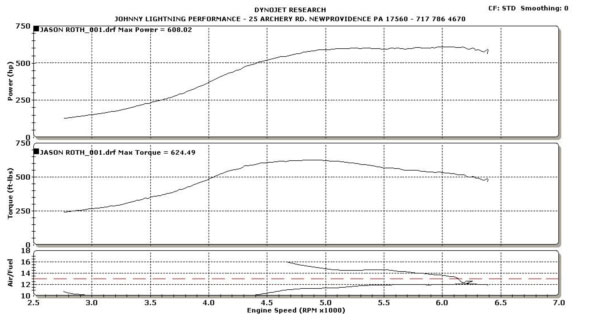

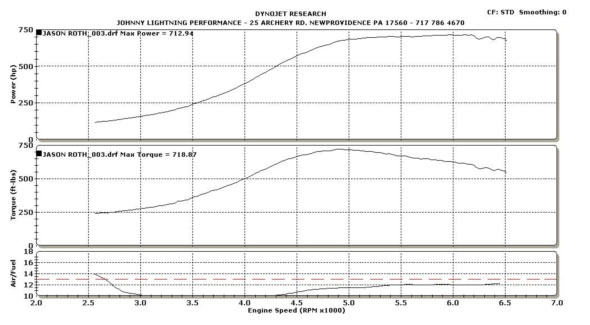

to date the car has been

put on the dyno twice. both have been

dynojets, however they have been at two

different speed shops. the first shop the car

was dyno�ed with the 0.81 a/r and the second

shop it was dyno�ed with the 0.96 a/r. the

outside temps and humidity were different, so

unfortunately i am unable to really compare

the two exhaust housings. however, from the

knowledge of others and turbonetics, the

larger exhaust housing would change the spool

up time and should increase power and torque

as well in the upper rpm ranges. my

experiences are that it takes approximately

200-300 rpm more to spool, which is hardly

noticeable and it does hold power higher in

the rpm range. it appears to make more

horsepower and hold it and appears to hold the

torque a little longer with less of a drop off

than with the 0.81 a/r exhaust housing. the

following graphs are from a dyno day we had at

johnny lightning performance in feb. 06�.

the following was with

15# of boost. the reason for the a/f reading

looking wacky is that the sensor blew out of

the tailpipe.

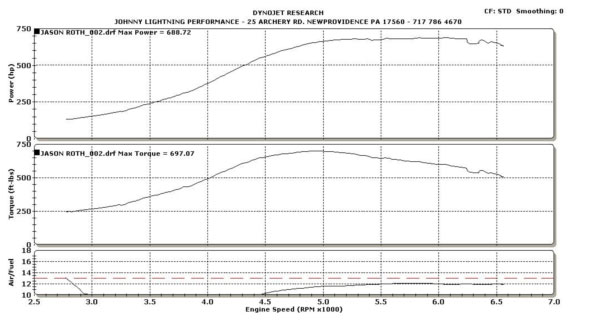

the following graph

was with 18#:

the final graph is

with 20.7#:

the car has not been

pushed over this amount of boost on the dyno.

i do not feel the need to max out the turbo

system for the sake of numbers. my goal for

the dyno is to determine the differences

between modification changes and for fun with

other car enthusiasts. the kit has made up to

847 rwhp in new mexico on another 03/04 cobra

at approximately 25# of boost.

there are now multiple

hellion 03/04 cobra�s running around the

united states and so far none have had

installation issues and have been basic bolt

on kits for those with many years of mechanic

experience and those with very minimal

experience. with no cutting required, basic

tools, customer service and the kits shipping

within days of ordering, this kit is by far

one of the best out on the market for proven

performance, reliability and cost. it is very

easy to duplicate the tuning and installation

with this kit. my tuner is jon lund of

lund racing and now has the same kit on

his car. the best my car has gone is 10.49 @

137.64 on 21.5# of boost. the car weighs

3900# with driver. at that mph with a better

60-foot it should go 10.20�s to 10.30�s at

that weight.

i am now in the process

of learning how to launch and get out of the

hole better with a turbo and manual

transmission. this is not an easy thing to do

with a turbo car and manual transmission. we

are changing things around with the tune,

2-step and timing retard.

please contact myself

(jason) with any questions you may have

regarding purchase, installation or general

questions about the kit and my experiences.

special thanks goes to

sean martin (blk03svtcobra) for the assistance

with writing this article.

|